Interlocking Auto Door is essential in factory especially for chemical industry. This is due to control the product quality, safety, and contamination which are critical.

However, the most advanced cleanroom facilities can fail if the entry and exit points are not properly controlled. This is where Interlocking Auto Door Systems play a vital role.

In this article, you’ll learn how Interlocking Auto Door for Factory ensure the cleanroom will improve contamination control & safety.

Why Chemical Factories Need Cleanrooms?

Before we try to understand why Interlocking Auto Door plays an important role, we need to know what is the cleanrooms.

In a chemical factory, a cleanroom is a controlled environment where chemicals are handled, mixed, or packaged.

Its vital purpose is critical is to control the product’s purity and the safety of the operators.

Thus this area is more cleaner than standard manufacturing facilities.

What Is An Interlocking Auto Door?

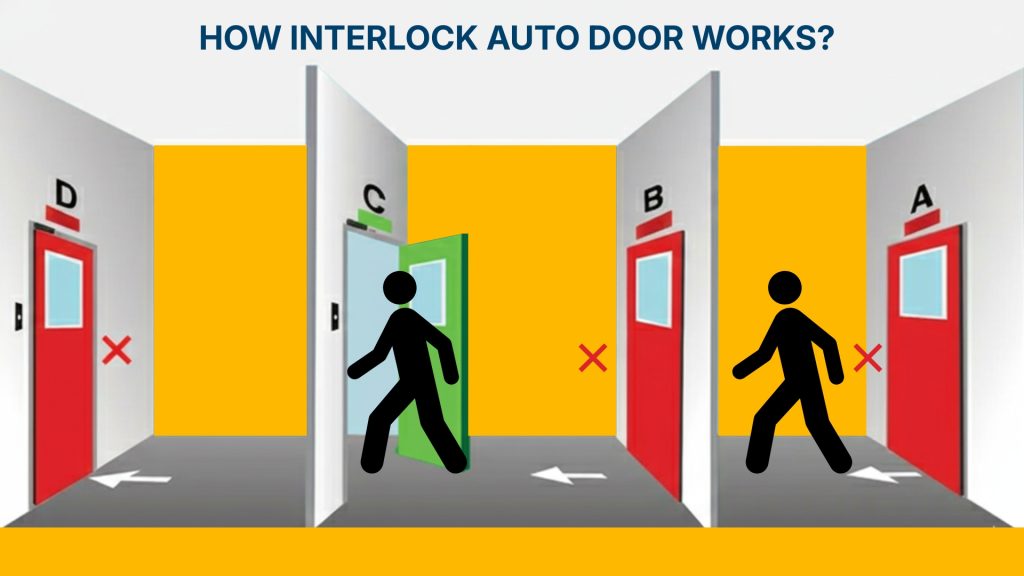

An interlocking door system (also called airlock door, interlocked entry, or mantrap) is a set of two or more doors where only one door can open at a time.

It controls movement between different rooms to maintain:

- Cleanliness

- Safety

- Air pressure

- Security

- Chemical containment

If Door A is open → Door B automatically stays locked

If Door B is open → Door A stays locked

Why Interlocking Auto Doors Are Used?

Interlocking auto doors serve critical purposes such as:

1. Prevent Contamination

Interlocking auto door create physical airlocks between zones. This results in one door only can be open in one time. To open the door into the next zone, the door behind must be fully closed and sealed. So, it prevents cross-contamination from a dirty area to a clean one.

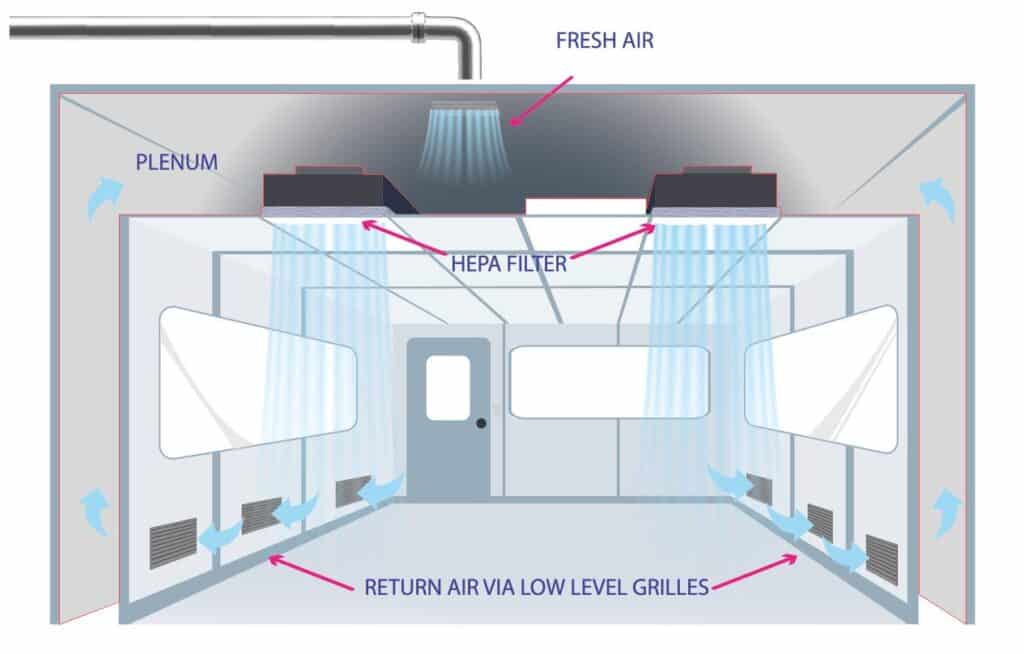

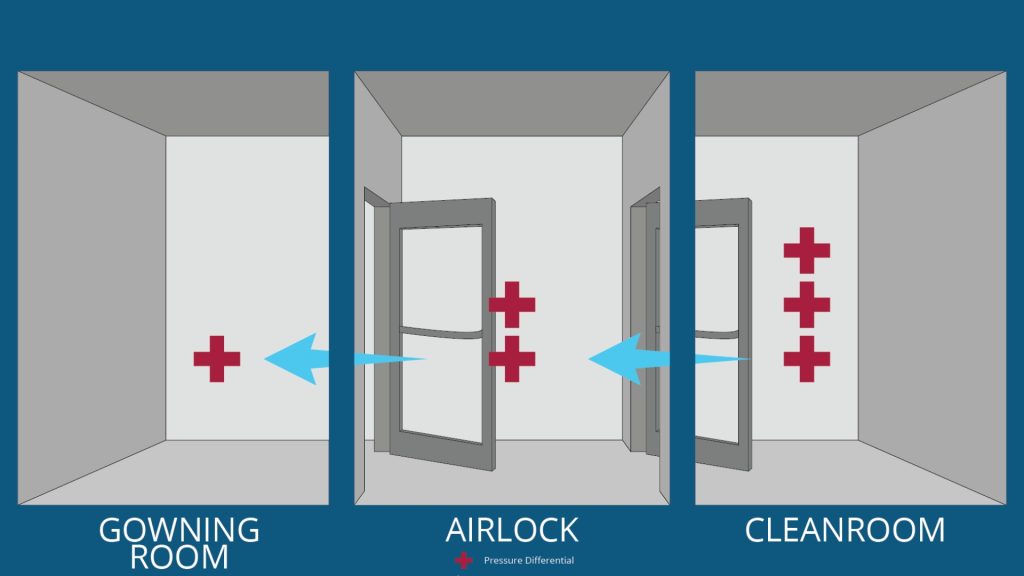

2. Maintain Air Pressure

Maintaining correct air pressure is vital for containment. Cleanrooms use positive pressure to keep contaminants out, while chemical rooms use negative pressure to trap hazardous vapors inside and prevent them from escaping.

3. Improve Safety

Prevents people from rushing in/out, especially if chemicals or gases are inside.

By enforcing strict operating conditions, a door interlocking system secures sensitive areas. It locks down one door before allowing another to open, which eliminates the hazard of simultaneous access and ensures precise control.

4. Security & Access Control

This system enhances security by controlling personnel access to restricted zones. It ensures only authorized entry, streamlining the flow of people and proactively addressing security risks.

They can integrate with:

- Card access

- Biometric readers

- CCTV

- Alarm systems

What Component Involves?

A standard door interlocking system integrates the following key components:

Auto Doors

The physical barriers (sliding or swing type). For example, VIRTUO Auto Door System is an ideal recommendation for your chemical factory Interlocking Auto Door setup.

Electromagnetic Lock (EM Lock)

Secures the doors in place. (For swing door only)

Door Sensors

Monitors whether a door is open or closed.

Interlock Controller

The central brain that processes all signals.

Door Access Control System

The user interface for security measures that designed to limit and control workers access to certain areas or resources within a facility. Click here to see Door Access Control System options.

Indicator Lights

Provides visual status (red or green) for example; safe to proceed or wait.

How An Interlocking Auto Door System Works?

Door Interlocking System Sequence of Operation

1. Verification:

An authorized user presents their credential for access (biometric/card/pincode) at the first door. The Door Access Control System verifies the user’s authorization. Upon success, it sends a “request to open” signal to the Interlock Controller.

2. Situation Check & Command:

The Interlock Controller checks the status of all doors via the Door Sensors. If the sequence is correct, the next door is confirmed locked), the controller sends an unlock command to the first door’s Electromagnetic Lock and signals the Auto Door to open.

3. User Passing & Monitoring:

The Indicator Light turns green, signaling the user to proceed. The user enters and the Auto Door closes automatically behind them. Door Sensors continuously monitor this action, confirming to the controller when the door is fully closed and locked.

4. Next Door Activation:

Only after the first door is confirmed sealed will the Interlock Controller repeat the process (Steps 2-4) for the next door in the sequence, allowing the user to continue safely.

Which Area Can Utilize Door Interlock Systems?

Beside a chemical cleanroom, few places also can be equipped with Interlocking Auto Door to prevent contamination and ensure safety for the workers.

1. Gowning room

This is the designated changing room where personnel wear their Personal Protective Equipment (PPE). It acts as the first barrier to prevent outside contaminants from entering the clean environment.

2. Material airlock

This is the decontamination gateway for all equipment, tools, and raw materials. Nothing can enters the main cleanroom without being processed here. Therefore, an Interlocking Auto Door is a must to ensure almost zero contamination happens.

3. Mixing / formulation room

This is the core processing area where the primary chemical reactions or product blending occurs. Without proper entry/exit prevention measures, it can possibly foul the formulation or chemical mixture.

4. Solvent handling area

A dedicated and secure zone for storing and handling flammable or volatile solvents. For example, the Interlocking Auto Door potentially saves the situation during fire as it block the passage for the fire to reach.

5. QC Laboratory

To test product samples for purity, concentration, and other specifications without sending them far from the cleanroom. Hence, any possible contamination can be minimized.

6. Packing room

Any contamination here such as dust, fibers, or airborne particles will be sealed into the final product. Redo the entire previous cleanroom process will add on cost, time, efficiency and energy.

End Note

Interlocking door systems are an essential upgrade for any facility aiming for higher quality, safety, and operational efficiency. It provide a robust access control that directly mitigates risks, reduces human error, and ensures stringent environmental conditions are consistently met.

Upgrade your Chemical Factory today with Interlocking Auto Door and for peace of mind and total protection from unseen threats!

For more details, contact us for a consultation. We provide installation for Interlocking Auto Door